- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 2 Author: Site Editor Publish Time: 2025-10-23 Origin: Site

Plastic moulding forms the foundation of modern manufacturing, turning raw polymers into the intricate shapes and structures that define contemporary life—from your car’s dashboard to the water bottle in your hand. For engineers, designers, and manufacturers, understanding the main moulding techniques is crucial for achieving optimal design performance, controlling costs, and selecting suitable materials.

While the industry employs many specialized and hybrid methods, five principal plastic moulding processes account for most products made worldwide: Injection Moulding, Blow Moulding, Extrusion Moulding, Compression Moulding, and Rotational Moulding (Rotomoulding).

Each process operates on its own combination of heat, pressure, and containment principles, producing parts tailored for different geometries, materials, and production scales.

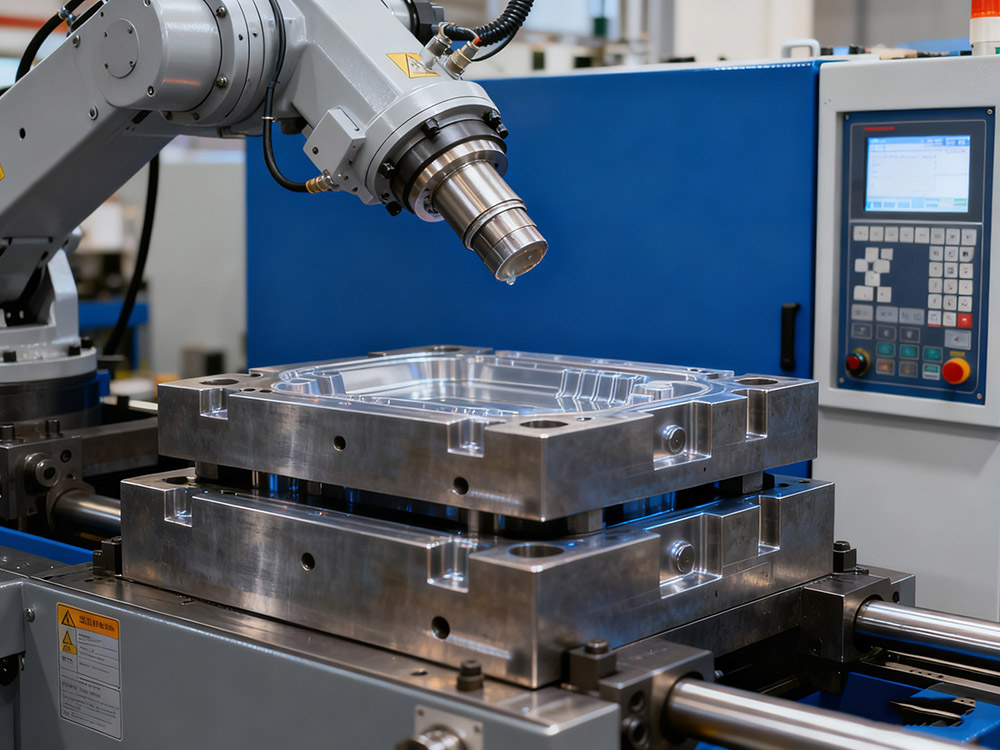

Injection moulding is the most common and versatile method in plastic manufacturing. It is ideal for creating solid components with detailed geometry, tight tolerances, and smooth surface finishes.

Preparation: Plastic pellets are fed from a hopper into a heated barrel.

Melting & Mixing: A reciprocating screw melts the plastic, mixes it, and pushes it toward the nozzle.

Injection: The molten plastic is injected into a closed, cooled mould cavity under high pressure.

Cooling & Solidification: The plastic rapidly cools inside the mould.

Ejection: Once solidified, the mould opens and ejector pins push the finished part out.

Feature | Details |

Geometry | Highly complex, multi-featured, solid parts. |

Volume | Extremely high (millions of parts). |

Cost | High tooling investment but low per-unit cost. |

Cycle Time | Very short—seconds to minutes. |

Applications | Automotive parts (dashboards, bumpers), electronic housings, medical syringes, toys, bottle caps, cutlery. |

Injection moulding offers unmatched dimensional accuracy and is the top choice for parts requiring overmoulding or insert moulding.

Blow moulding is designed to produce hollow plastic objects with thin, consistent walls. This process powers the production of most bottles, containers, and tanks. As the name implies, it involves blowing compressed air into a heated plastic preform, inflating it against the mould walls.

Two major variants exist:

Extrusion Blow Moulding: A molten plastic tube (parison) is extruded vertically. The mould closes around it, pinching one end shut. Compressed air is then blown in, expanding the parison to the mould’s shape.

Injection Blow Moulding (IBM) & Stretch Blow Moulding (ISBM): A preform (resembling a test tube) is first injection moulded, reheated, stretched (in ISBM), and then inflated. This method is widely used for PET bottles that require clarity and strength—like water and soda bottles.

Feature | Details |

Geometry | Hollow, seamless forms (bottles, drums, tanks). |

Volume | High, especially for consumer packaging. |

Cost | Moderate tooling and low unit cost. |

Cycle Time | Very fast—ideal for high-speed production lines. |

Applications | Water bottles, detergent containers, fuel tanks, seating shells, and plastic drums. |

Blow moulding is highly material-efficient and essential for producing strong, lightweight containers using materials like PET.

Unlike other methods that produce discrete items, extrusion moulding creates continuous products with a fixed cross-section—similar to squeezing toothpaste through a shaped nozzle. It’s the most economical way to manufacture long, uniform plastic profiles.

Feeding & Melting: Plastic pellets are introduced into a heated barrel containing a rotating screw.

Continuous Flow: The screw melts the material and forces it through a die, which shapes the molten plastic.

Shaping & Cooling: The extruded form exits the die, is cooled (often in a water bath), and solidifies.

Cutting: The continuous length is cut to required sizes.

Feature | Details |

Geometry | Continuous, uniform profiles (rods, tubes, sheets). |

Volume | Exceptionally high for long-length products. |

Cost | Low tooling cost due to simple die design. |

Cycle Time | Continuous operation measured in meters/minute. |

Applications | PVC pipes, window frames, plastic sheeting, fencing, seals, and wire insulation. |

Extrusion moulding is the go-to process for continuous-length products and often serves as a precursor for other moulding types, such as blow moulding parisons.

Compression moulding is one of the earliest and simplest plastic moulding methods, widely used for thermoset plastics and large, durable components. It relies on heat and pressure to shape pre-measured material directly within the mould cavity.

Charge Placement: A set amount of preheated material (called a charge) is positioned inside the open, heated mould.

Compression: The upper mould half closes, applying high pressure to force the material to fill the cavity.

Curing: For thermoset materials, heat activates a chemical reaction that permanently hardens the plastic.

Ejection: Once cured, the part is removed; the mould remains hot for the next cycle.

Feature | Details |

Geometry | Large, thick, complex shapes with moderate precision. |

Volume | Moderate to high. |

Cost | Moderate tooling cost and low maintenance. |

Cycle Time | Slower than other methods due to curing time. |

Applications | Automotive panels (SMC/BMC composites), dinnerware (melamine), helmets, electrical components, large industrial parts. |

Compression moulding is ideal for thermoset and fiber-reinforced composites, maintaining fiber integrity and strength throughout the curing process.

Rotational moulding, or rotomoulding, is perfect for producing large, hollow, and seamless items with consistent wall thickness. Unlike high-pressure techniques, it relies on gravity and slow biaxial rotation rather than force.

Loading: A pre-measured amount of powdered plastic is placed into a split, cold mould.

Heating & Rotation: The mould is sealed and heated while rotating on two perpendicular axes.

Melting & Coating: The resin melts and evenly coats the mould’s interior surface.

Cooling: Still rotating, the mould is cooled until the plastic solidifies.

Demoulding: The finished part is removed once cooled.

Feature | Details |

Geometry | Large, hollow, seamless parts with uniform walls. |

Volume | Low to moderate. |

Cost | Lowest tooling cost—moulds are lightweight and simple. |

Cycle Time | Long (30 minutes to several hours). |

Applications | Water tanks, kayaks, playground equipment, outdoor planters, and traffic cones. |

Selecting the appropriate plastic moulding method depends on several core factors:

Part Geometry: Solid and complex (Injection), hollow (Blow/Rotational), or continuous (Extrusion)?

Production Volume: Millions of units (Injection/Extrusion/Blow) or smaller batches (Rotational/Compression)?

Material Type: Thermoplastics (Injection/Blow/Extrusion) or thermosets (Compression)?

Size & Wall Thickness: Thin-walled (Blow) or thick, large, uniform walls (Rotational)?

By mastering these five moulding techniques—Injection, Blow, Extrusion, Compression, and Rotational Moulding—manufacturers can meet virtually every plastic production need, from precision medical devices to massive industrial tanks.

For a clear visual overview of these processes, check out this video from Youtube: “Types of Plastic Molding Explained”