- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 12 Author: Site Editor Publish Time: 2025-11-02 Origin: Site

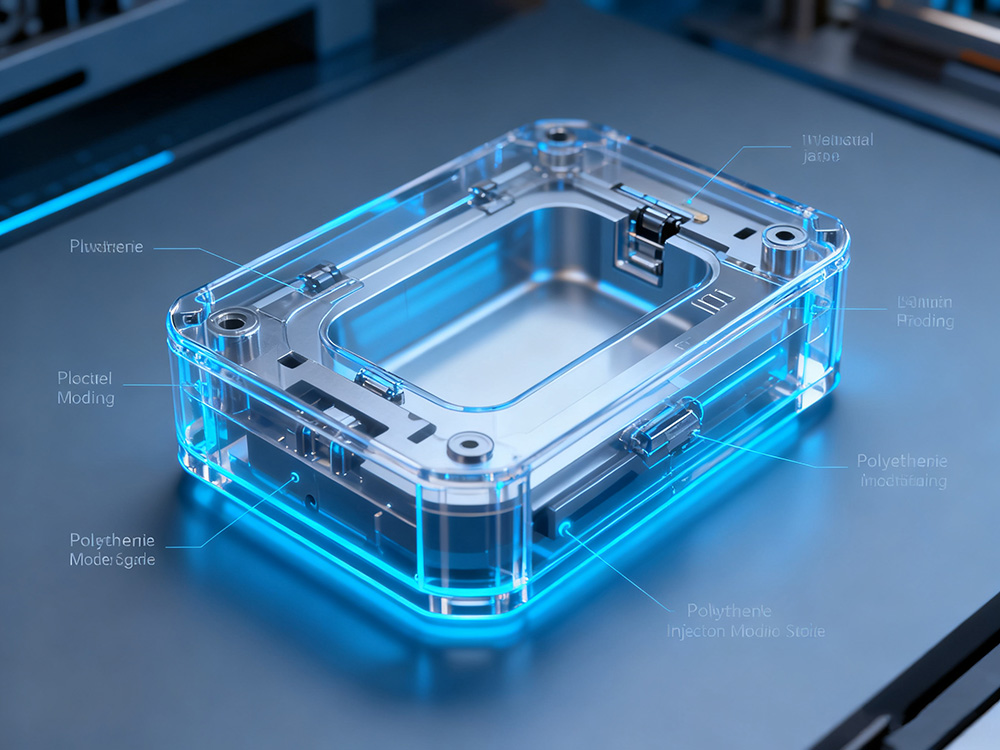

Polyethylene (PE) is one of the most widely used plastics in the world, known for its excellent chemical resistance, flexibility, and toughness. From packaging and consumer goods to automotive and industrial parts, this versatile polymer has earned a leading position in modern manufacturing. But one question often arises for engineers and designers: can polyethylene be injection moulded?

The answer is a definite yes — polyethylene can be effectively processed through injection moulding to produce high-quality, durable parts. In this guide, we’ll explain how and why, covering the properties of polyethylene, its processing behavior, key moulding parameters, advantages, and comparisons with other materials.

Polyethylene (PE) is a thermoplastic polymer made by the polymerization of ethylene monomers (C₂H₄). Its chemical structure consists of long chains of repeating –CH₂–CH₂– units, making it one of the simplest and most chemically stable plastics.

The polymer’s properties can vary significantly depending on its molecular weight, branching, and density. This is why polyethylene is available in several forms, each optimized for different applications.

1. Low-Density Polyethylene (LDPE)

Density: 0.910–0.940 g/cm³

Structure: Highly branched polymer chains

Properties: Soft, flexible, and transparent with excellent impact strength and moisture resistance.

Typical Uses: Plastic bags, squeeze bottles, wire insulation, and film packaging.

2. High-Density Polyethylene (HDPE)

Density: 0.941–0.965 g/cm³

Structure: Linear molecular chains with minimal branching

Properties: High stiffness, strength, and chemical resistance; low permeability to moisture.

Typical Uses: Containers, caps, toys, pipes, and household goods.

3. Linear Low-Density Polyethylene (LLDPE)

Density: 0.915–0.940 g/cm³

Structure: Linear chains with short, controlled branching

Properties: Combines strength and flexibility; better impact and tear resistance than LDPE.

Typical Uses: Stretch films, lids, and flexible packaging.

Because of its versatility, PE is found in:

Consumer goods (bottles, toys, kitchenware)

Packaging films and containers

Automotive components

Electrical insulation

Industrial piping and tanks

Yes — polyethylene is one of the most commonly injection-moulded thermoplastics.

Both LDPE and HDPE are widely processed through injection moulding to produce complex, high-precision parts.

The material’s low melting point, ease of flow, and chemical stability make it ideal for high-volume manufacturing. However, the specific processing conditions depend on the grade and type of polyethylene used.

Injection moulding is particularly suitable for producing caps, closures, containers, fittings, and small to medium-sized components where strength, impact resistance, and cost efficiency are priorities.

Polyethylene’s molecular structure gives it several characteristics that make it ideal for injection moulding:

Low Melting Temperature: Typically between 110°C and 140°C, allowing energy-efficient moulding cycles.

Excellent Flowability: Especially in LDPE and LLDPE grades, which makes it easy to fill complex mould cavities.

Good Thermal Stability: PE maintains consistent viscosity and stability at typical moulding temperatures.

High Chemical Resistance: Resistant to acids, bases, and most solvents, reducing post-moulding degradation.

Low Shrinkage and Warpage: Properly cooled parts maintain dimensional stability and surface finish.

These features contribute to polyethylene’s popularity across diverse injection moulding applications.

While the exact parameters depend on the PE grade, here are general guidelines for successful moulding:

Parameter | LDPE | HDPE |

Melt Temperature | 160–220°C | 180–250°C |

Mould Temperature | 20–50°C | 30–70°C |

Injection Pressure | 70–140 MPa | 70–120 MPa |

Holding Pressure | 30–80 MPa | 30–80 MPa |

Injection Speed | Moderate to high | Moderate |

Shrinkage Rate | 1.5–3% | 1.5–4% |

Key Tips:

Use drying only if necessary — polyethylene absorbs very little moisture.

Ensure uniform cooling to prevent sink marks or warping.

Optimize gate design and venting to allow smooth material flow and prevent trapped air.

Despite its advantages, polyethylene presents a few processing challenges that moulders should manage carefully:

Thermal Sensitivity: Overheating can cause degradation, producing smoke or discoloration.

Shrinkage: PE shrinks more than some plastics (like ABS), requiring precise mould design compensation.

Low Rigidity: Thin or long parts may deform during ejection or use if not properly reinforced.

Poor Paint and Adhesive Bonding: Due to its non-polar, waxy surface, surface treatment (corona or plasma) may be required for printing or painting.

Static Build-Up: Some grades accumulate static charges, attracting dust or debris.

Proper process control and mould design can minimize these issues effectively.

Injection moulded polyethylene offers numerous benefits that make it one of the most cost-effective choices in manufacturing:

Excellent Impact Resistance: Performs well under stress, even at low temperatures.

Lightweight: Reduces shipping and handling costs.

Chemical and Moisture Resistance: Ideal for harsh or outdoor environments.

Recyclable: PE is one of the most recycled plastics worldwide.

Cost-Effective: Inexpensive raw material and efficient moulding cycles lower production costs.

Good Electrical Insulation: Common in electrical housings and insulation components.

These features make PE particularly valuable for industries that require durable, economical, and high-volume production parts.

Injection moulded PE is used in thousands of everyday products, including:

Packaging and Containers: Lids, caps, food containers, and storage bins.

Consumer Goods: Toys, household products, tool handles, and protective cases.

Automotive Components: Fuel tanks, cable insulation, and lightweight housings.

Industrial Products: Pipe fittings, valves, and chemical-resistant components.

Medical and Laboratory Items: Syringe plungers, tubing connectors, and sample containers.

HDPE, in particular, is popular in rigid parts, while LDPE and LLDPE are preferred for flexible, impact-resistant designs.

Let’s see how polyethylene stacks up against other common plastics in injection moulding.

PE vs. PP (Polypropylene)

Similarities: Both are lightweight, chemically resistant, and economical.

Differences:

- PP has higher stiffness and heat resistance.

- PE has better impact strength at low temperatures.

- PP offers superior dimensional stability.

Best Use: PE for flexible, impact-resistant parts; PP for rigid, heat-resistant components.

PE vs. ABS (Acrylonitrile Butadiene Styrene)

ABS: More rigid and better for precision parts with tight tolerances.

PE: More flexible and impact resistant, especially for outdoor applications.

Surface Finish: ABS is easier to paint and bond than PE.

Cost: PE is generally cheaper and more chemically resistant.

PE vs. PVC (Polyvinyl Chloride)

PVC: Excellent rigidity and flame resistance but contains chlorine, raising environmental concerns.

PE: Non-toxic, easier to recycle, and more flexible.

Thermal Processing: PE processes at lower temperatures with less degradation risk.

Summary Table: Key Performance Differences

Property | PE | PP | ABS | PVC |

Density | Low | Low | Medium | High |

Rigidity | Low–Medium | Medium–High | High | High |

Impact Strength | Excellent | Good | Good | Moderate |

Heat Resistance | Moderate | High | High | Moderate |

Chemical Resistance | Excellent | Excellent | Moderate | Excellent |

Recyclability | Excellent | Excellent | Good | Moderate |

Cost | Low | Low | Medium | Medium |

So, can polyethylene be injection moulded?

Absolutely — and it’s one of the most versatile and economical materials to use in this process.

Polyethylene’s balance of strength, flexibility, chemical resistance, and low cost makes it a top choice for producing consumer goods, packaging, automotive parts, and industrial components. With proper processing control, LDPE, HDPE, and LLDPE can all deliver excellent performance in injection moulded applications.

Whether you’re designing a new product or optimizing production, polyethylene offers a combination of processability, durability, and sustainability that’s hard to beat.