- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 6 Author: Site Editor Publish Time: 2025-10-30 Origin: Site

Polymethyl methacrylate (PMMA), commonly known as acrylic or trade names such as Plexiglas and Lucite, is one of the most widely used transparent plastics in modern manufacturing. PMMA injection molding has become a preferred production method for creating clear, durable, and visually appealing components across industries—from automotive lenses and medical devices to consumer electronics and lighting products.

In this article, we’ll explore what PMMA injection molding is, how the process works, the material’s properties, temperature requirements, best practices, and why it remains one of the most valuable materials for transparent plastic parts in 2025 and beyond.

PMMA is a thermoplastic polymer derived from methyl methacrylate (MMA) monomers. It’s known for its exceptional optical clarity, lightweight nature, and high surface hardness. Often referred to as “acrylic,” PMMA serves as a lightweight, shatter-resistant alternative to glass.

Unlike glass, PMMA can be molded into intricate shapes while maintaining transparency and durability, making it ideal for both functional and decorative parts.

PMMA’s popularity in injection molding comes from its unique balance of optical transparency, strength, and ease of processing. Its melt behavior and stable viscosity allow for the creation of precise, high-quality components with excellent surface finishes.

Manufacturers choose PMMA injection molding when:

Optical clarity is essential (e.g., lenses, screens, light guides).

A smooth, glossy surface finish is desired.

Resistance to UV radiation and weathering is required.

A lightweight, glass-like appearance is needed.

Common Applications

PMMA injection molding is widely used in:

Automotive lighting: Headlamp covers, taillight lenses.

Consumer electronics: Display panels, indicator covers, LED diffusers.

Medical devices: Syringe barrels, diagnostic lenses, protective housings.

Lighting and architecture: Light diffusers, lamp covers, skylights.

Household goods: Cosmetic packaging, furniture components, aquarium tanks.

PMMA is a synthetic polymer produced by the polymerization of methyl methacrylate (MMA) monomers. Its repeating molecular structure gives it rigidity, excellent optical transmission (up to 92%), and superior weatherability.

Chemical formula:

Property | Description |

Transparency | Up to 92% light transmission—clearer than glass |

Density | ~1.18 g/cm³ (half the weight of glass) |

Hardness | Excellent surface hardness and scratch resistance |

UV Resistance | Outstanding weatherability and color stability |

Heat Deflection Temperature | 95–110°C |

Tensile Strength | ~65 MPa |

Impact Strength | Lower than PC but higher than PS |

Recyclability | 100% recyclable thermoplastic |

Comparison with Other Transparent Plastics

Material | Optical Clarity | Impact Strength | Heat Resistance | Cost | Weather Resistance |

PMMA | ★★★★★ | ★★☆☆☆ | ★★★☆☆ | Moderate | Excellent |

PC (Polycarbonate) | ★★★★☆ | ★★★★★ | ★★★★☆ | High | Good |

PS (Polystyrene) | ★★★☆☆ | ★☆☆☆☆ | ★★☆☆☆ | Low | Poor |

PET | ★★★★☆ | ★★★☆☆ | ★★★☆☆ | Moderate | Good |

Summary:

PMMA offers the best optical quality and surface hardness, though it is more brittle than PC. For parts where clarity and aesthetics outweigh impact resistance, PMMA is the top choice.

While PMMA offers many advantages, it also comes with limitations:

Lower impact resistance compared to PC.

Brittle under stress—can crack under impact or tight fitting.

Limited heat resistance (softens above ~100°C).

Requires careful drying before molding to avoid bubbles and haze.

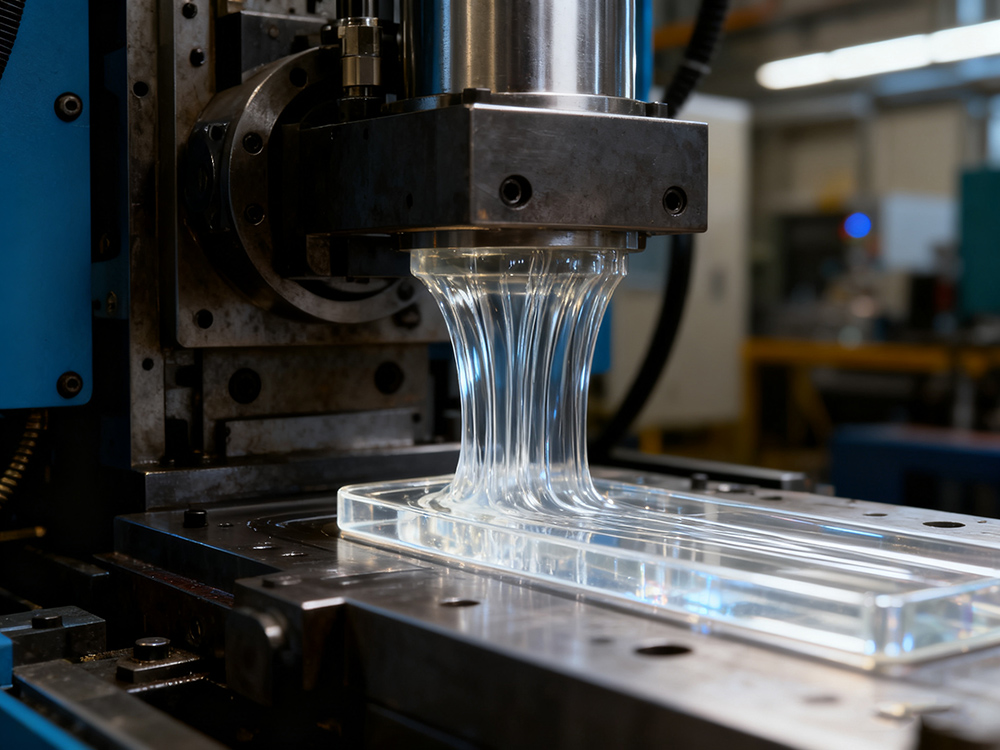

The PMMA injection molding process involves melting acrylic pellets and injecting them into a mold under high pressure to form the desired shape.

Material Preparation (Drying)

PMMA absorbs moisture easily. Before molding, it must be thoroughly dried (at 80–90°C for 2–4 hours) to prevent moisture-induced defects such as splay marks and bubbles.

Melting and Plasticizing

The dried granules are fed into the injection molding machine, where they are heated and melted. The melt temperature is typically maintained between 200–250°C, depending on the grade.

Injection into the Mold Cavity

The molten PMMA is injected under pressure (700–1400 bar) into a clean, polished mold cavity. Proper venting is critical to avoid trapped air that can cause optical defects.

Cooling and Ejection

The mold is cooled uniformly to prevent internal stress and warping. Once solidified, the part is ejected carefully to avoid surface damage.

PMMA is highly sensitive to temperature fluctuations. Overheating can cause discoloration or degradation, while underheating can lead to incomplete filling and poor transparency. Maintaining stable melt and mold temperatures is crucial for optical quality.

Machine and Mold Setup

Screw type: General-purpose or optical-grade screw.

Mold temperature: 60–90°C (higher for thicker parts).

Injection speed: Moderate to high, to prevent weld lines.

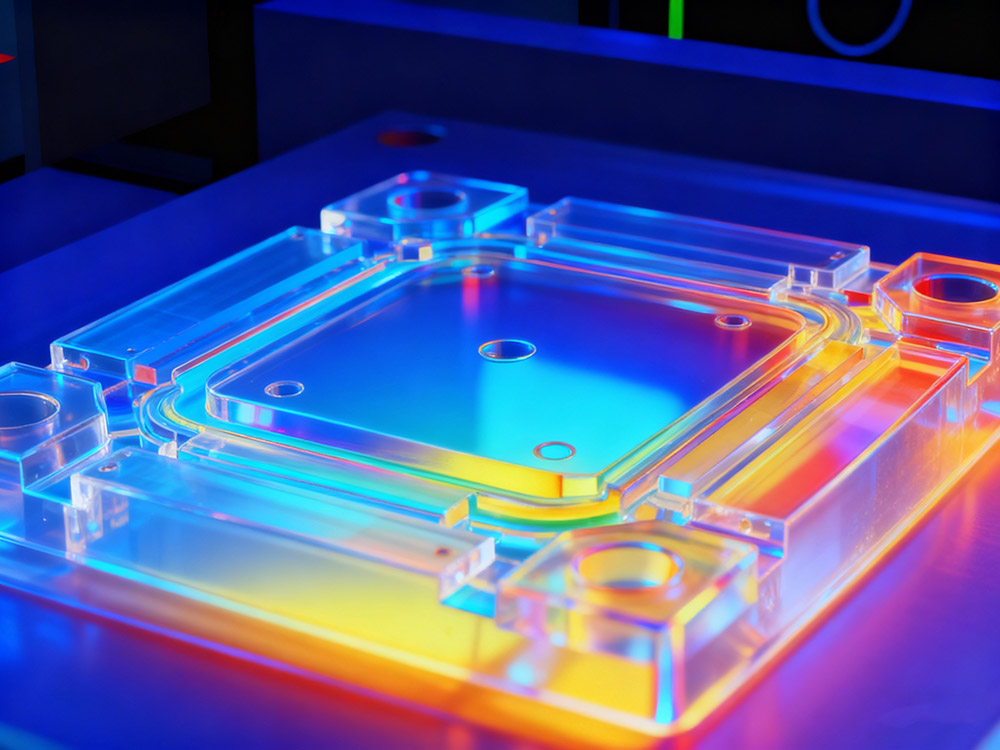

Mold material: Polished steel or chrome-plated surface for high clarity.

Clean, Dry, and Polished Molds Are Essential

Since PMMA parts are often transparent, any contamination or imperfection in the mold will be visible on the finished product. Molds should be:

Free of oil, dust, or residue.

Highly polished (mirror finish).

Properly vented to eliminate trapped gases.

The optimal temperature settings vary depending on grade and manufacturer, but typical parameters are:

Stage | Temperature Range |

Barrel/Melt Temperature | 200–250°C |

Nozzle Temperature | 220–240°C |

Mold Temperature | 60–90°C |

Drying Temperature | 80–90°C |

Maintaining consistent temperature profiles is key to preventing internal stress, haze, and color shifts.

Proper drying ensures a bubble-free, optically clear product.

Drying temperature: 80–90°C

Drying time: 2–4 hours

Moisture content before molding: <0.05%

Using a dehumidifying dryer is recommended for large-scale production.

Yes — PMMA is relatively easy to mold, though it requires precise control of processing conditions. It flows well in molten form, allowing for detailed shapes and thin-walled components, but it is sensitive to shear and heat.

To achieve excellent results:

Avoid excessive injection pressure to prevent internal stress.

Maintain uniform cooling.

Use well-polished molds for transparent parts.

Automotive Industry – Headlight and taillight lenses, indicator covers.

Lighting Fixtures – LED diffusers, light pipes, skylight panels.

Medical Devices – Transparent housings, surgical instrument components.

Consumer Goods – Cosmetic bottles, display cases, furniture decor.

Electronics – Screen covers, optical discs, smart device panels.

Signage and Advertising – Illuminated letters, display panels.

PMMA is preferred whenever optical performance and surface quality are essential.

Ensure complete drying before molding.

Avoid overheating — degradation causes yellowing or bubbles.

Polish mold surfaces to achieve mirror-like finishes.

Optimize gate design to reduce weld lines and air traps.

Use moderate injection speed to maintain flow and clarity.

Control cooling to minimize internal stress.

Avoid sharp corners — design with rounded edges to prevent cracking.

Post-process annealing can relieve internal stresses for optical parts.

Advantages

High transparency and gloss (up to 92% light transmittance).

Excellent weather and UV resistance.

Good rigidity and dimensional stability.

Easily moldable into complex geometries.

Chemical resistance to dilute acids and alkalis.

Polishable surface for optical applications.

Recyclable and environmentally friendly.

Limitations

Brittleness and low impact strength compared to PC.

Limited heat resistance (softens near 100°C).

Moisture-sensitive, requires drying.

Prone to stress cracking under mechanical load.

Higher cost than PS or ABS in some markets.

PMMA injection molding remains one of the most important processes for manufacturing high-quality transparent plastic parts. Its balance of optical clarity, rigidity, and weather resistance makes it ideal for automotive, medical, lighting, and consumer applications.

However, success in PMMA molding depends heavily on precise temperature control, proper material drying, and clean, polished molds. When handled correctly, PMMA can produce parts with stunning visual quality that rival glass in beauty but outperform it in versatility and durability.

As industries continue to push for lightweight, aesthetic, and sustainable materials, PMMA injection molding will remain a vital solution for transparent component production in the years ahead.