- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 9 Author: Site Editor Publish Time: 2025-09-18 Origin: Site

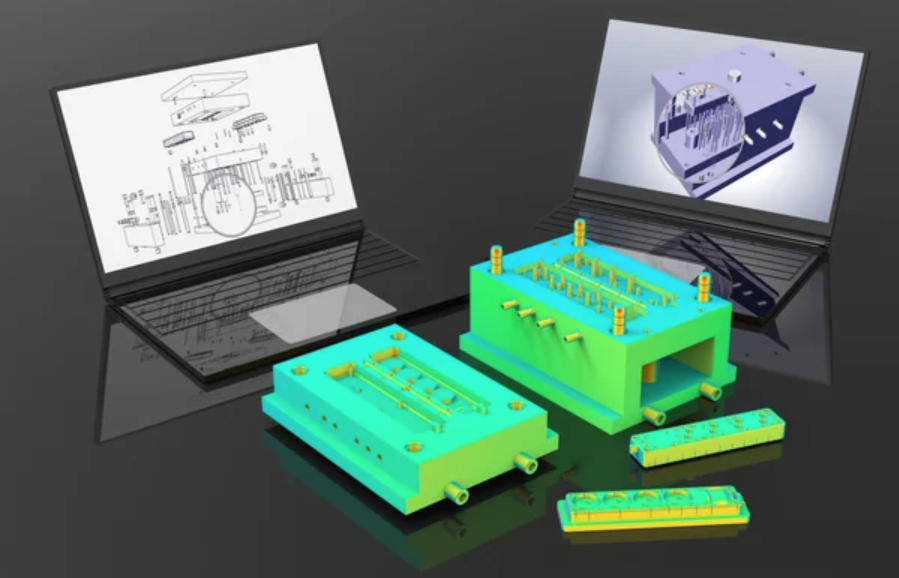

Injection molding is one of the most widely used manufacturing processes for producing plastic parts in high volume with consistent quality. At the heart of this process lies the injection mold design—a critical step that determines not only the efficiency of production but also the performance, durability, and cost-effectiveness of the final product.

A well-designed mold reduces cycle time, minimizes defects, and prolongs tool life. On the other hand, poor design choices can lead to warpage, sink marks, excessive scrap, or costly maintenance. Whether you are an engineer, a product designer, or a manufacturer, understanding the key factors in injection mold design is essential for successful project execution.

This article explores in depth the factors to consider in injection mold design, covering technical, material, and economic perspectives to guide you toward creating effective and reliable molds.

Before diving into the factors, it’s important to understand what injection mold design entails.

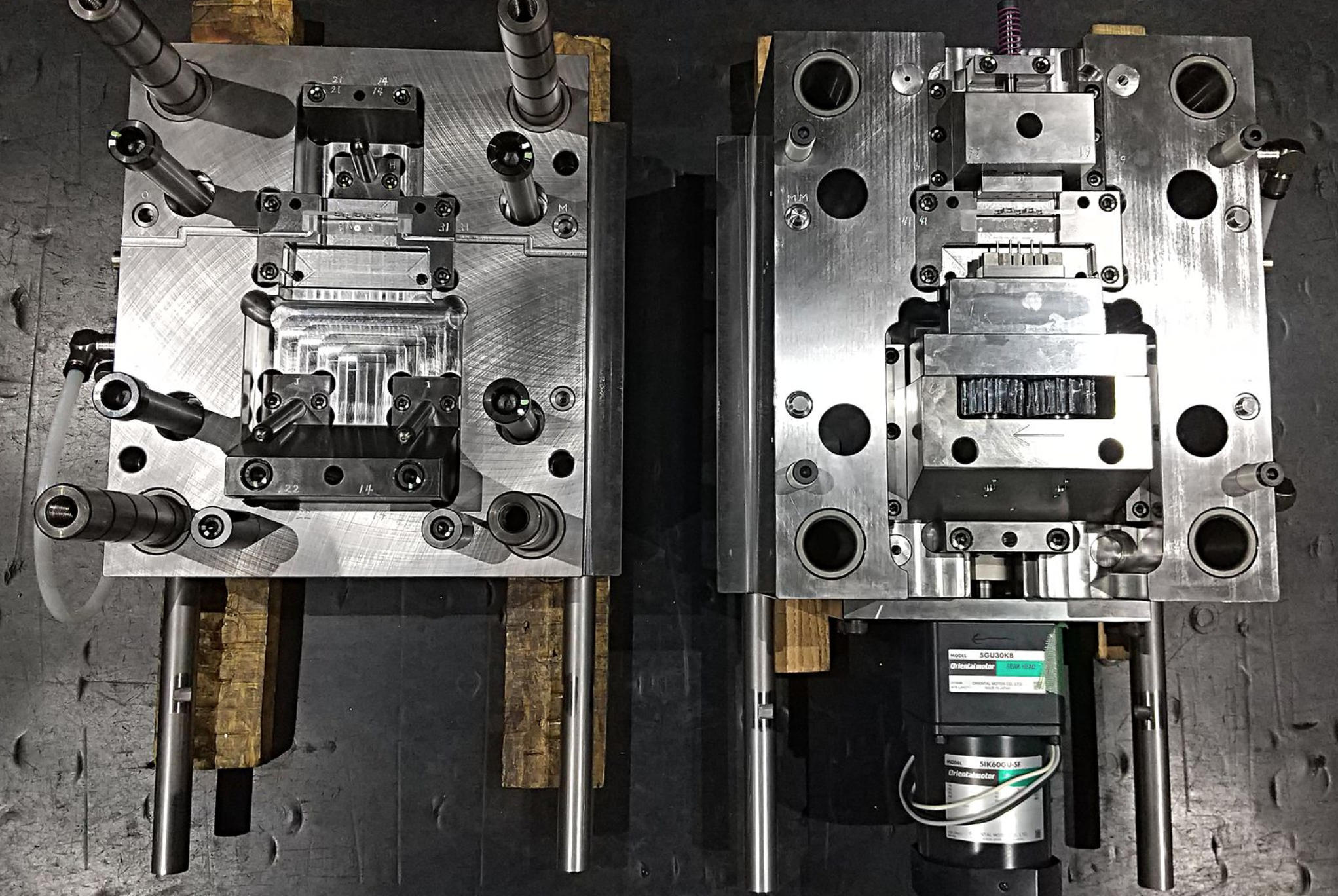

An injection mold is a precision tool usually made of hardened steel or aluminum, which creates plastic parts by shaping molten resin under high pressure. The mold typically consists of two halves:

Core half (stationary side)

Cavity half (moving side)

When these halves close, they form a cavity that matches the shape of the desired product. Molten plastic is injected into this cavity, cooled, and then ejected to produce the finished part.

Thus, mold design involves determining how these components work together, taking into account material flow, cooling, ejection, strength, and manufacturability.

The design of the part itself is the first factor influencing mold design. Complex geometries can complicate mold construction, increase costs, and lengthen cycle times.

Wall Thickness: Uniform wall thickness is critical to prevent warpage, shrinkage, and sink marks. Sudden changes in thickness should be avoided.

Draft Angle: Adding a draft angle (typically 1–2°) helps with easy part ejection, reducing stress on the mold and the plastic part.

Ribs and Bosses: Features like ribs add strength but must be designed carefully to avoid thick sections that can cause sink marks.

Undercuts: Undercuts may require side actions or lifters, which add complexity and cost to the mold.

The choice of plastic resin significantly affects mold design.

Thermoplastics vs. Thermosets: Thermoplastics like ABS or polypropylene have different flow and cooling requirements compared to thermosets.

Shrinkage Rate: Each material shrinks differently upon cooling. Mold cavities must account for this shrinkage to ensure accurate final dimensions.

Chemical Resistance and Strength: Certain applications (e.g., medical, automotive) demand materials that can resist chemicals, heat, or impact, which influences mold construction.

Deciding the number of cavities in a mold affects production efficiency and cost.

Single-Cavity Molds: Lower cost, easier to maintain, but less efficient for high-volume production.

Multi-Cavity Molds: Higher output per cycle, but require precise balance of melt flow and cooling to maintain quality.

Family Molds: Multiple parts in one mold, ideal for assemblies, but must be carefully designed to avoid uneven filling.

Mold base materials directly impact durability and cost.

Hardened Steel: Best for long production runs; more expensive but durable.

Pre-hardened Steel: Suitable for medium runs, easier to machine.

Aluminum: Lower cost, faster machining, ideal for prototypes or short runs, but limited lifespan.

The choice depends on the production volume, resin type, and budget.

Cooling is one of the most critical elements in mold design because it directly affects cycle time.

Cooling Channels: Must be strategically placed to ensure uniform cooling. Poor cooling design can cause warpage or uneven shrinkage.

Conformal Cooling: Advanced method using 3D printing to create cooling channels that follow the contour of the part.

Cooling Time: Often accounts for 60–70% of the cycle, so optimization here saves significant cost.

The gate is the entry point where molten plastic flows into the cavity. Its type and placement affect flow, filling, and appearance.

Gate Types: Edge gate, pin gate, submarine gate, hot runner gate, etc.

Location: Must minimize weld lines, air traps, and flow hesitation.

Size: Too small causes incomplete filling; too large leaves excessive vestige.

The runner directs the molten plastic from the sprue to the gates.

Cold Runner: Simple and cost-effective but wastes material.

Hot Runner: Eliminates material waste and improves cycle times but is more expensive and complex.

Choosing the right system depends on cost, part requirements, and production volume.

Vents allow trapped air and gases to escape from the mold during injection.

Poor venting can cause burns, short shots, or poor surface finish.

Vents are usually 0.02–0.05 mm deep to allow gas out without flashing plastic.

Once the part solidifies, it must be ejected without damage.

Ejector Pins: Common method, but must be placed strategically to avoid visible marks.

Stripper Plates: Useful for delicate parts.

Air Ejection: Helps release thin-walled or flexible parts.

A poorly designed ejection system can deform parts or damage the mold.

Injection molds must meet strict tolerances to ensure product consistency.

Tolerances: Influenced by material shrinkage, tool wear, and machine capability.

Surface Finish: Polished, textured, or matte finishes depend on product requirements.

Modern injection mold design relies heavily on simulation software.

Predicts flow, pressure, cooling, and warpage before actual mold manufacturing.

Identifies potential issues like weld lines, sink marks, or voids early.

Mold design decisions should align with expected production volume.

High-volume production: Invest in durable steel, multi-cavity molds, hot runners, and optimized cooling.

Low-volume production: Aluminum molds, cold runners, or simplified designs are more cost-effective.

Mold longevity depends on ease of maintenance.

Inserts, bushings, and wear plates should be replaceable.

Access to cooling channels and ejector pins must allow easy cleaning and repair.

For industries like medical devices, food packaging, or automotive, compliance with standards is non-negotiable.

FDA, ISO, or automotive-specific certifications may dictate design choices.

Mold must prevent contamination, ensure precision, and support regulatory documentation.

While technical considerations are crucial, economics play a decisive role in mold design:

Initial Tooling Cost: High upfront investment, especially for multi-cavity steel molds.

Production Efficiency: Optimized cooling and gating reduce cycle time, lowering per-part cost.

Material Usage: Hot runners minimize waste, but may not justify cost for small runs.

Return on Investment (ROI): Designers must balance upfront cost against long-term production benefits.

Even experienced designers can make errors. Common mistakes include:

Ignoring draft angles, causing ejection issues.

Poor venting, leading to burn marks.

Uneven cooling, causing warpage.

Misplaced gates, resulting in weld lines.

Overcomplicated designs, raising unnecessary costs.

Technology is reshaping mold design practices:

3D Printing (Additive Manufacturing): Enables rapid prototyping and conformal cooling channels.

AI and Simulation: Smarter mold flow analysis with predictive adjustments.

Sustainability Focus: Designing molds for recycled materials and energy-efficient production.

Digital Twin Technology: Creating a virtual replica of the mold to monitor performance and predict maintenance.

Injection mold design is both an art and a science. From part geometry and material selection to cooling, gating, venting, and cost considerations, each factor plays a role in ensuring efficient production and high-quality results. A well-designed mold reduces cycle times, prevents defects, and ensures long-term reliability, while a poorly designed one can lead to expensive downtime and quality issues.

By carefully evaluating all the factors in injection mold design—technical, material, and economic—you can create molds that deliver precision, durability, and profitability. As new technologies like AI and 3D printing emerge, the future of mold design will be even more optimized, efficient, and sustainable.